In an industry as time-honored as charcoal production, innovation might seem unexpected. Yet, the dawn of unique charcoal factory design is challenging conventions, blending environmental sustainability with technological advancements. This exploration into the world of innovative charcoal manufacturing facilities reveals how unique design principles are not only enhancing production efficiency but also contributing to a greener planet.

Pioneering Sustainability in Design

At the heart of unique charcoal factory design lies a commitment to sustainability. Forward-thinking manufacturers are integrating renewable energy sources, such as solar and biomass, into their factory operations. These initiatives significantly reduce the carbon footprint associated with charcoal production, setting a new standard for environmental stewardship in the industry.

Efficiency Through Innovation

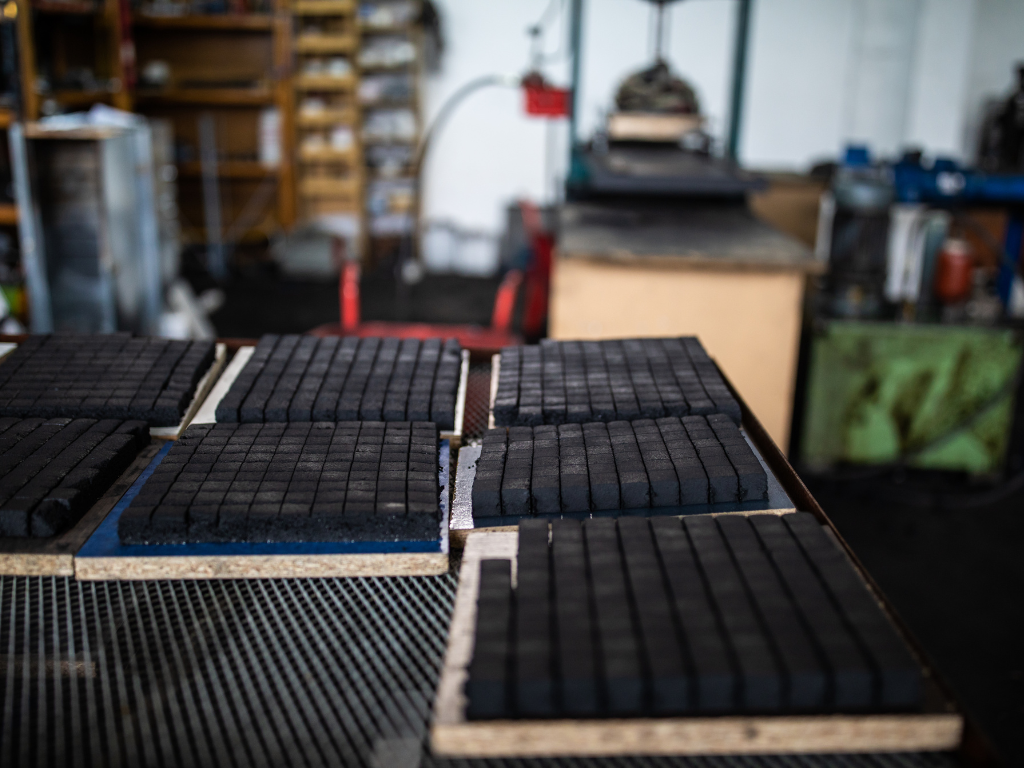

The evolution of charcoal factory design is marked by an emphasis on increasing operational efficiency. Innovative layouts and machinery are optimized for maximum productivity, ensuring that every step of the charcoal production process, from carbonization to packaging, is streamlined. This not only boosts output but also minimizes waste, showcasing how intelligent design can lead to more sustainable manufacturing practices.

Architectural Aesthetics Meet Industrial Functionality

Unique charcoal factory design also extends to the architectural aspect, where functionality meets aesthetics. Some factories are becoming architectural landmarks in their own right, with designs that reflect the natural landscapes around them or utilize eco-friendly materials in construction. These buildings not only serve their primary purpose but also demonstrate how industrial facilities can positively contribute to their surroundings.

Embracing Local Materials and Traditions

Innovative charcoal factories are increasingly turning to local materials and traditional methods, albeit with a modern twist. By doing so, they not only reduce their environmental impact through lower transportation emissions but also support local economies. This approach fosters a closer connection between the factory and its community, reinforcing the importance of sustainable and socially responsible manufacturing.

The Challenge of Change

Transitioning to unique charcoal factory designs is not without its challenges. High initial investment costs, navigating regulatory landscapes, and shifting market demands are significant hurdles. However, the long-term benefits of these innovative designs, both environmentally and economically, provide a compelling case for embracing change.

The Future is Bright and Bold

The future of charcoal production looks bright with the advent of unique factory designs that prioritize sustainability, efficiency, and aesthetic appeal. As more manufacturers embrace these innovative principles, the industry is set to undergo a transformative shift. This movement not only heralds a new era for charcoal production but also serves as an inspiration for other sectors to consider how design can play a crucial role in achieving sustainability goals.